Foraged Found Dyes

–Food Waste Dye

Natural dyes have a long history of use in the textile industry, offering sustainable and eco-friendly alternatives to synthetic dyes. This study investigates the potential of food waste as a source of natural dyes and examines how these dyes interact with different types of fibers. The research question for this study is: “How would food waste dye sources react on different fibers (natural and synthetic)?”

METHODOLOGY

I followed the following steps to achieve my results.

Solar Dye

Extracting colour from plant materials using sunlight

Steps:

- Use boiling hot water to extract colour from the dye source.

- Add cold water to the extracted source, mix and pour the liquid into a sealable container. Leave enough room for fibers. (Usually the ratio of dye source and fiber is 1:1)

- Dip fibers several times in the dye liquid until well soaked. Do not take the fibers out, leave them in the container and ensure the liquid covers the top of the fibers.

- Seal the container and place it in an area where it receives direct sunlight for a few days.

- Check the jar daily. Once the dye liquid turns clear, the dye process is complete.

- Rinse and air dry the fiber.

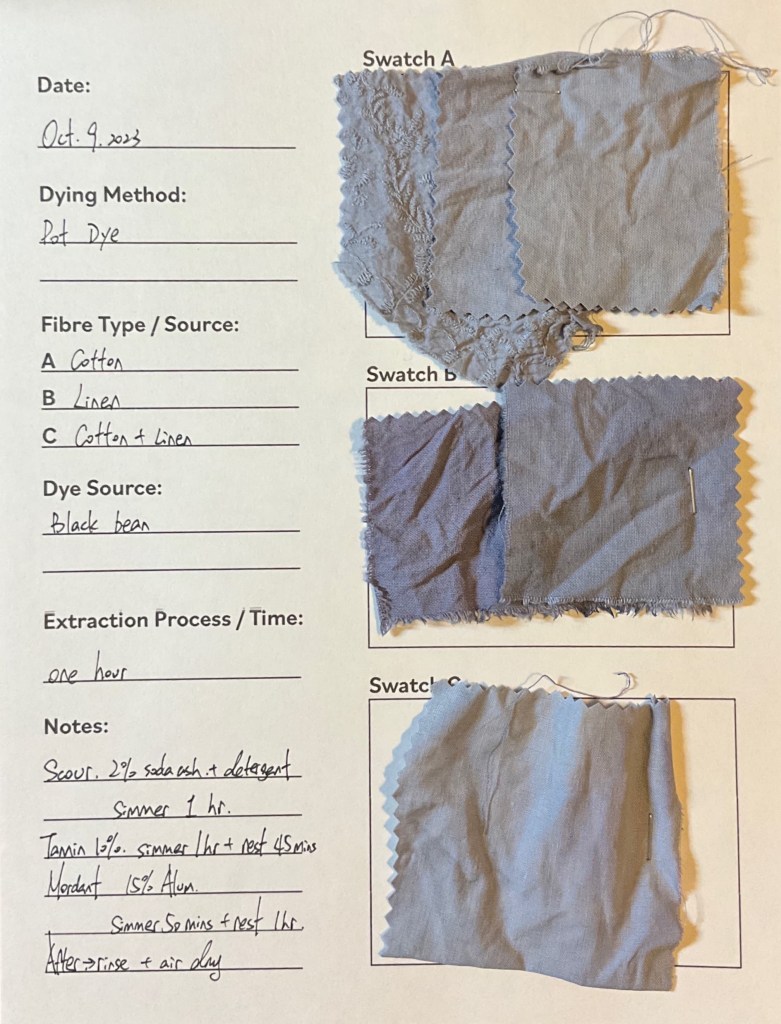

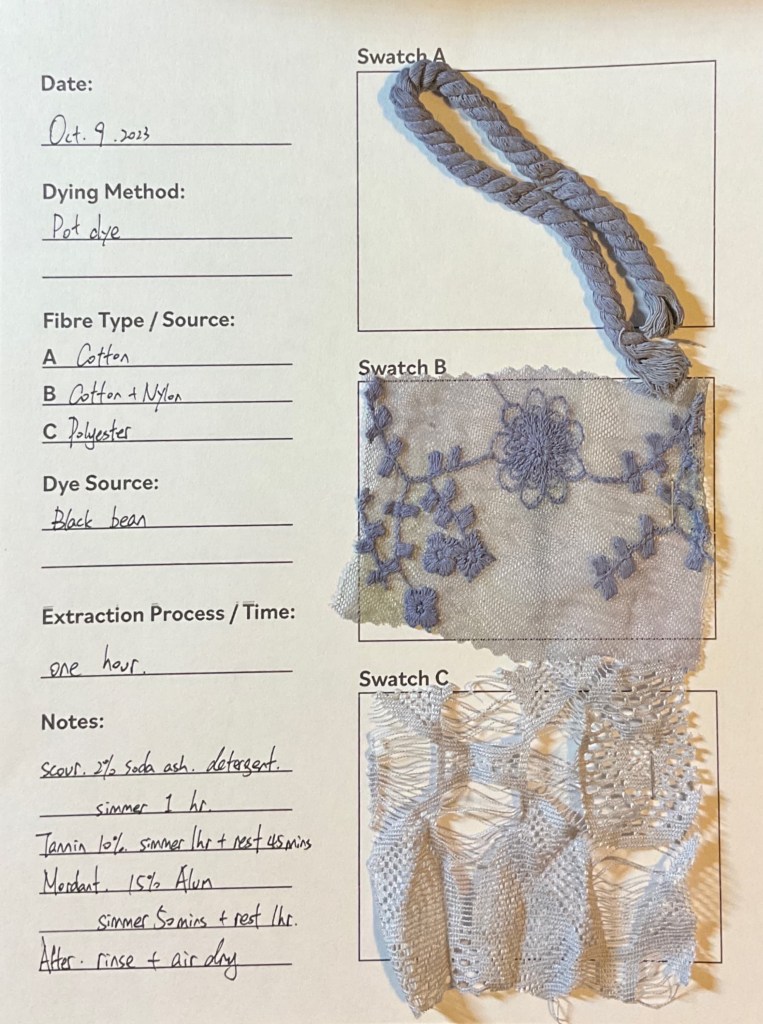

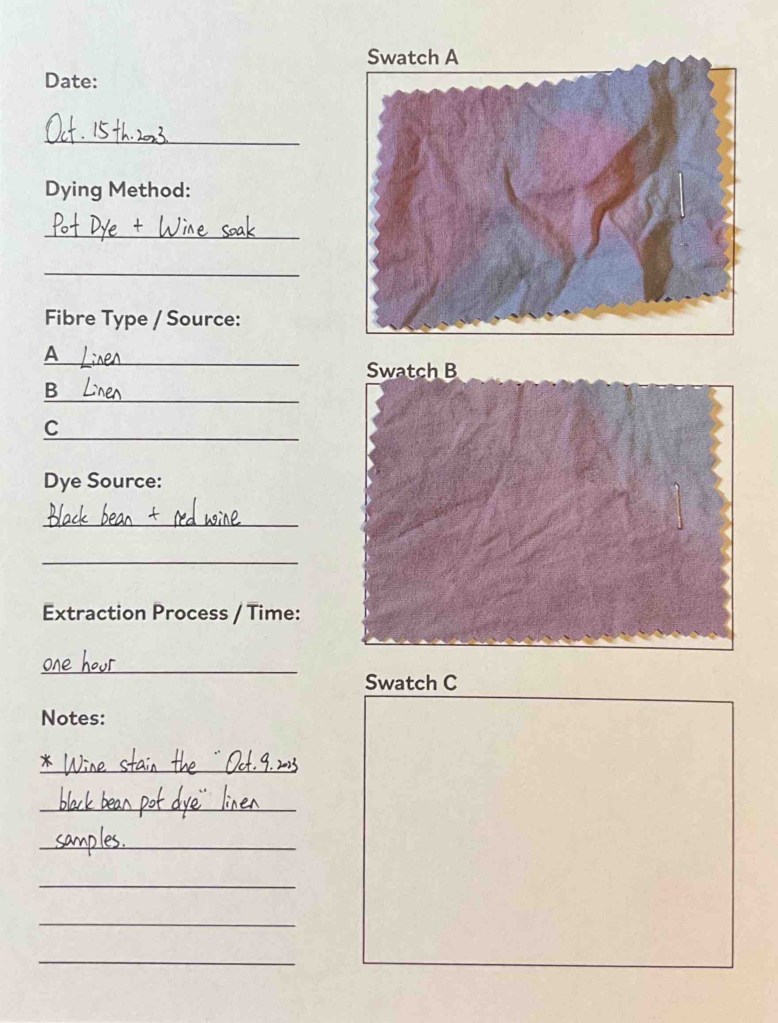

Pot Dye

Dyeing fabrics or yarns using a pot or a container on a heat source, such as a stove.

Steps:

- Add the dye source to a pot and fill in enough water to cover the dye source and dye material.

- Add the dye source into the pot, heat the pot and bring the water to the boil.

- Extract color from the dye sources by simmering them in hot water for hours.

- Reduce the temperature based on the fiber (e.g. Wool can only take up to 60 °C or it will start the felting reaction)

- Add the fiber to the pot and simmer for hours.

- Check and stir the pot frequently.

- Once the process is finished, take the fiber out, rinse and air dry.

DYE SOURCES

For Pot Dye

For Solar Dye

Avocado Pits & Skin / Onion Skin / Walnut Hull

Black Bean / Red Cabbage

FIBER PRE-TREATMENT

Scour

Cleaning and preparing fibers to be dyed by removing impurities, oils, waxes, and other substances that might hinder the absorption of natural dyes

Fibers were scoured with ash soda at a weight of 2% of the weight of the fabric (WOF), along with a splash of detergent. This mixture was simmered for an hour.

Tannin

Tannins can aid cellulose fibres in accepting colour

Tannin was applied at 10% of WOF and cooked/simmered for an hour, followed by a 45-minute rest.

Mordant

Mordant helps improve the colorfastness and permanence of the dye, ensuring that it adheres more effectively to the material being dyed.

Alum was used as a mordant at 15% of WOF, followed by cooking/simmering for 45 minutes and resting for an hour.

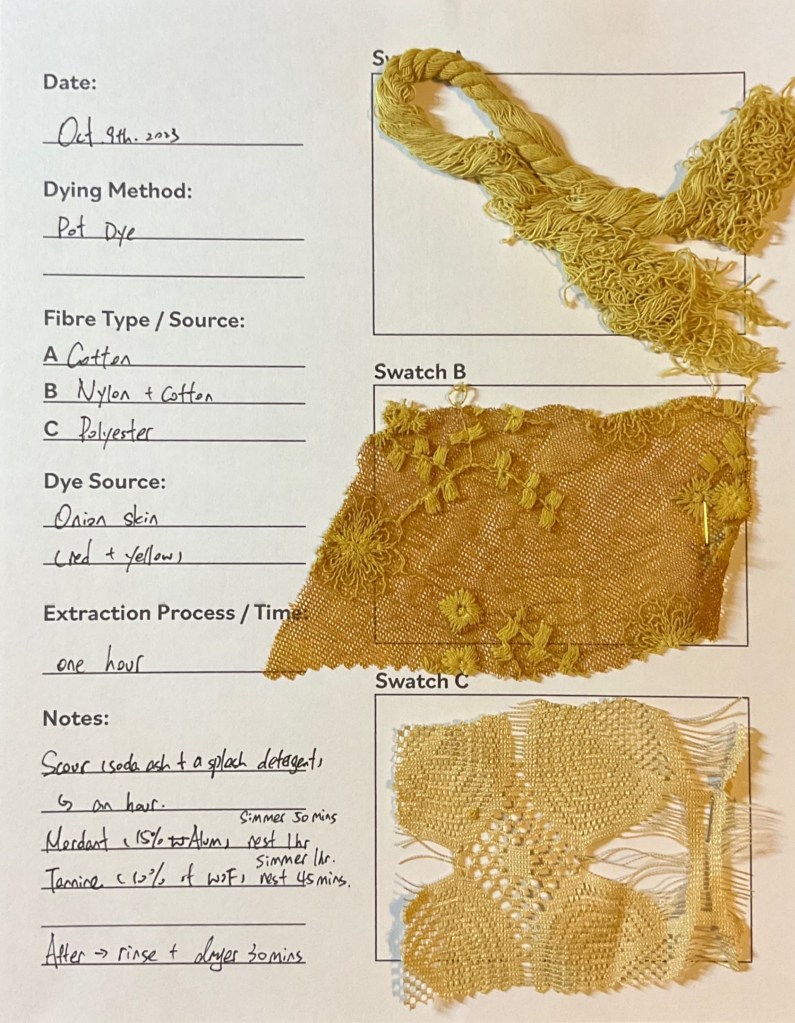

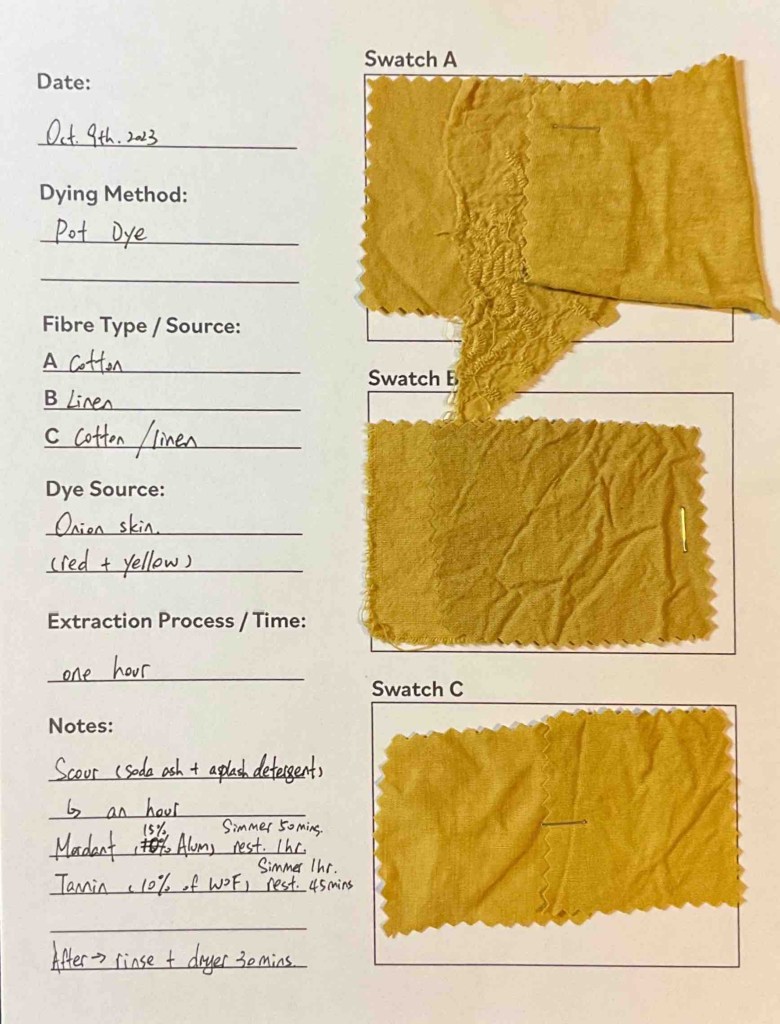

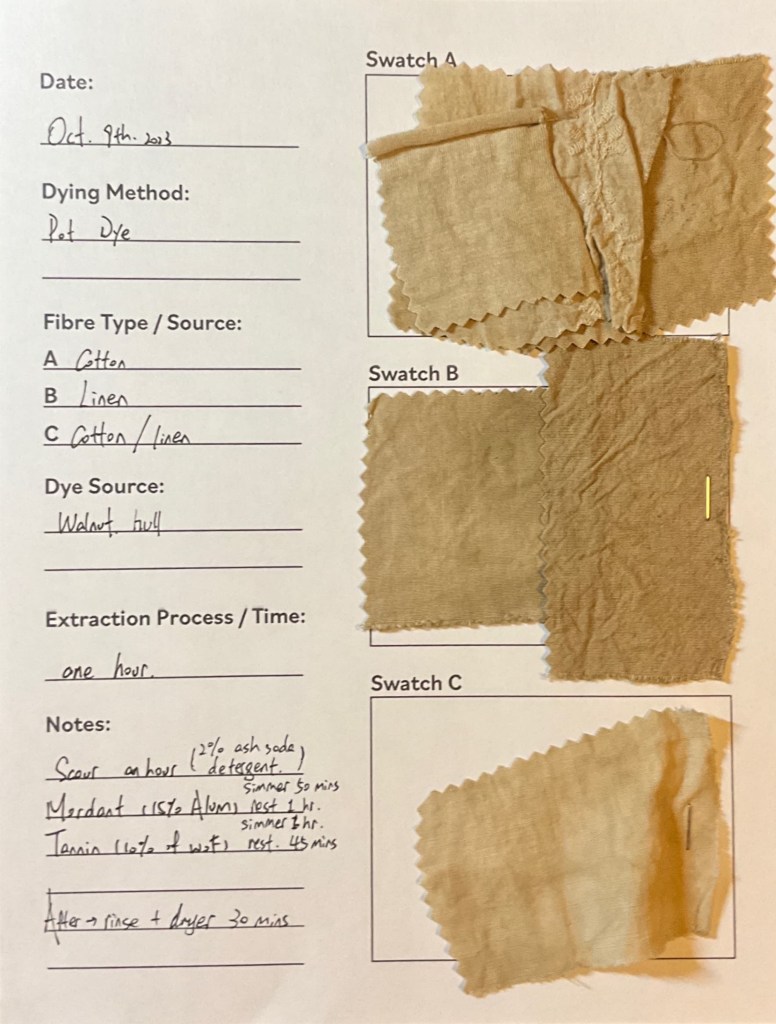

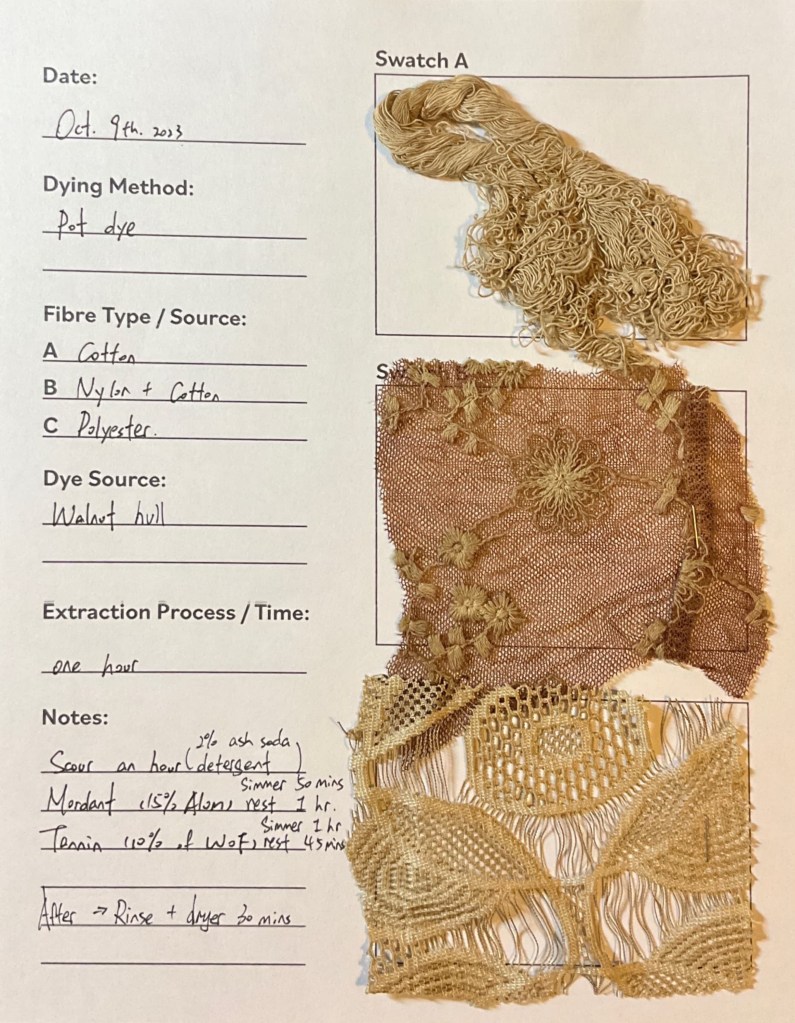

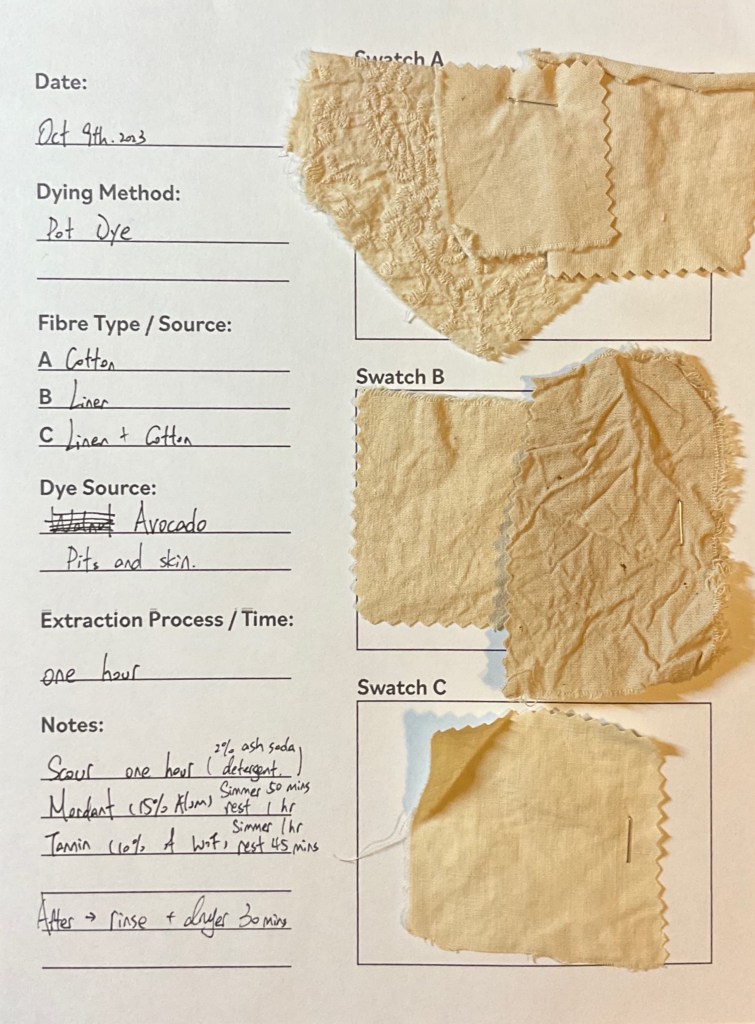

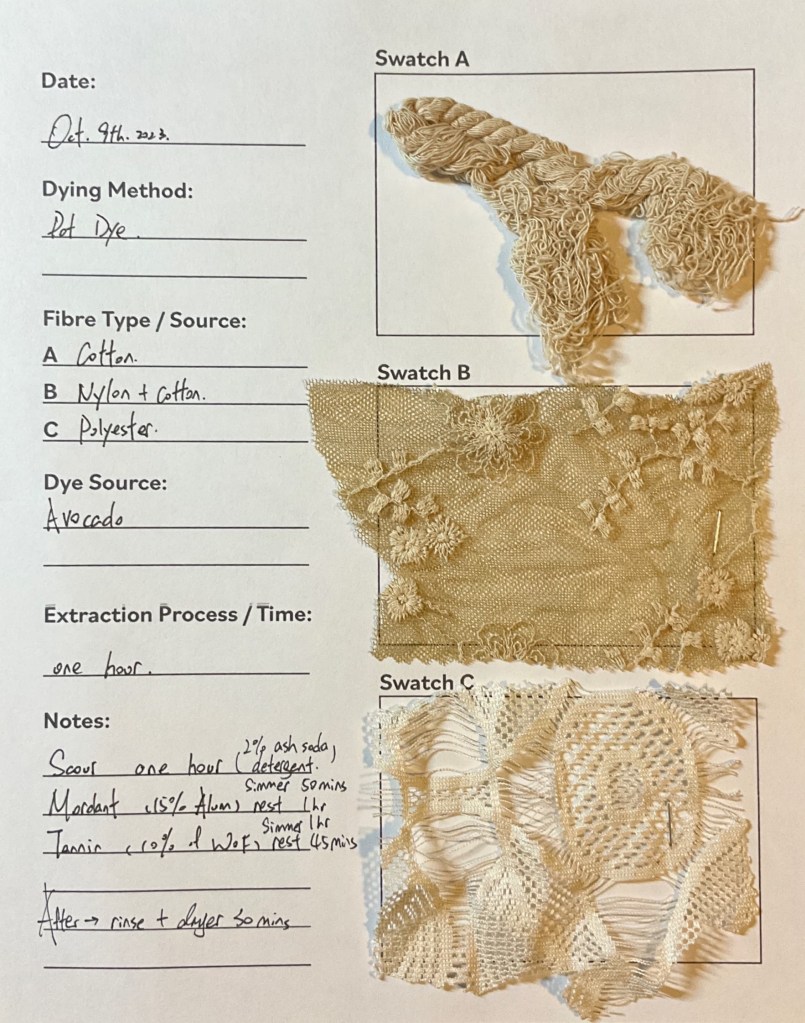

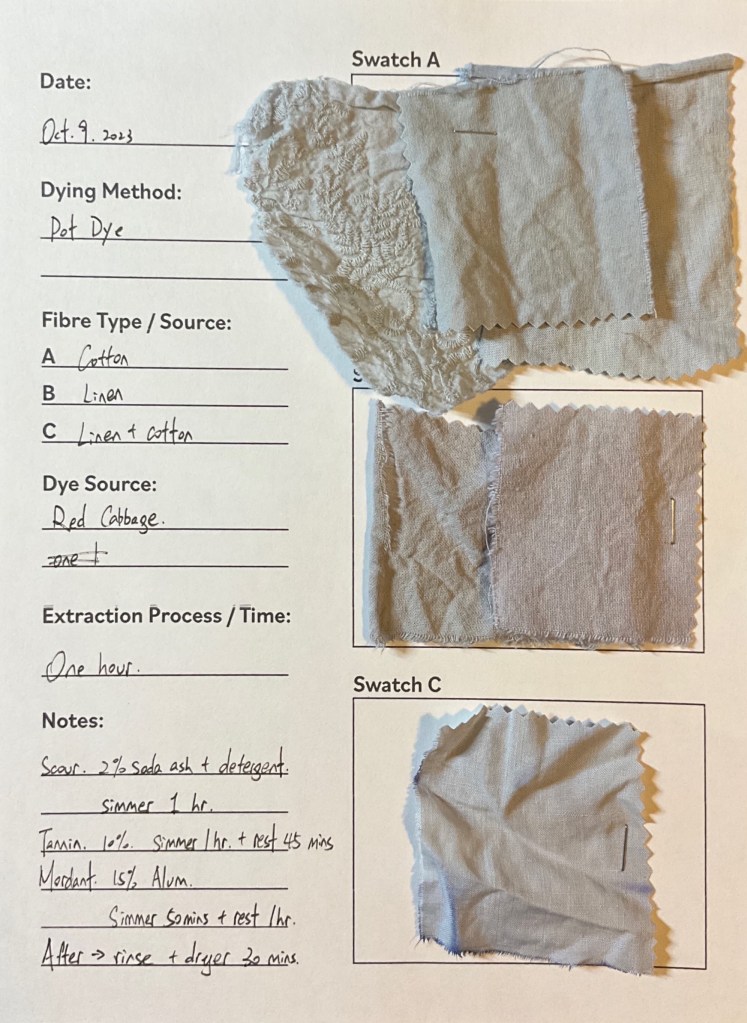

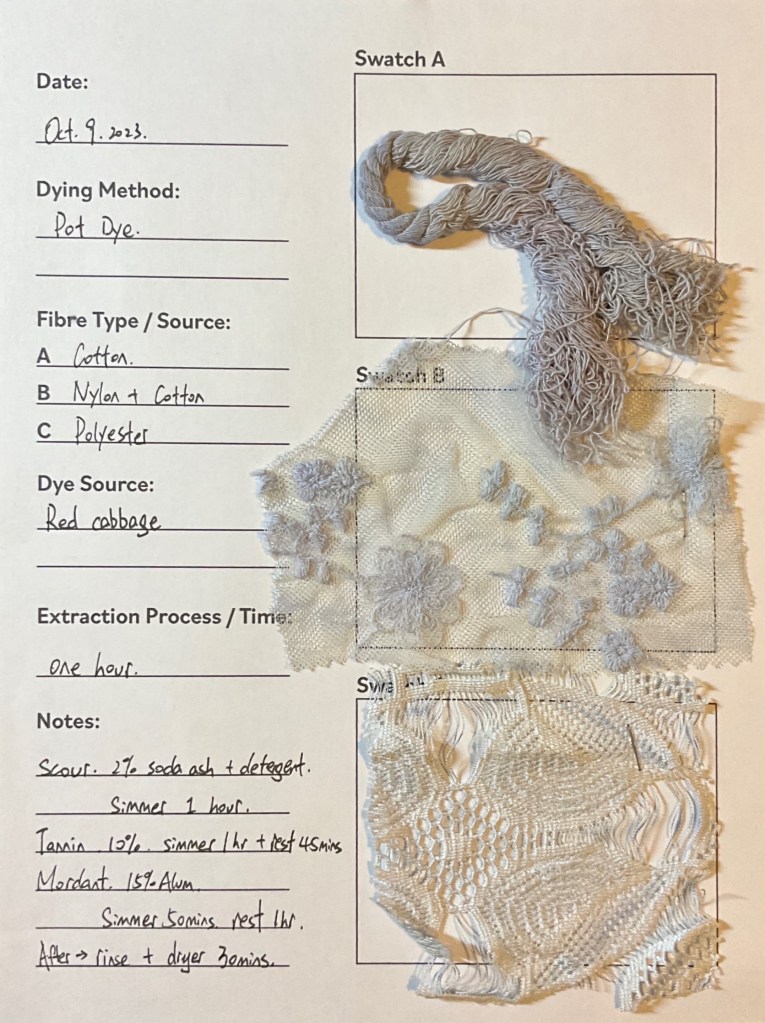

RESULTS