Weave the waste

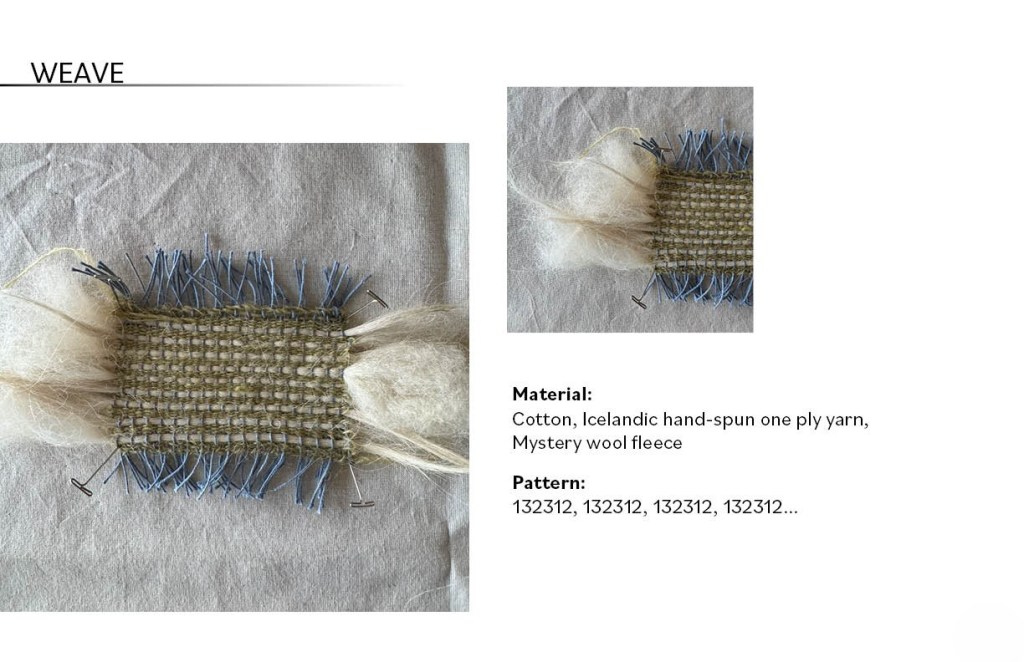

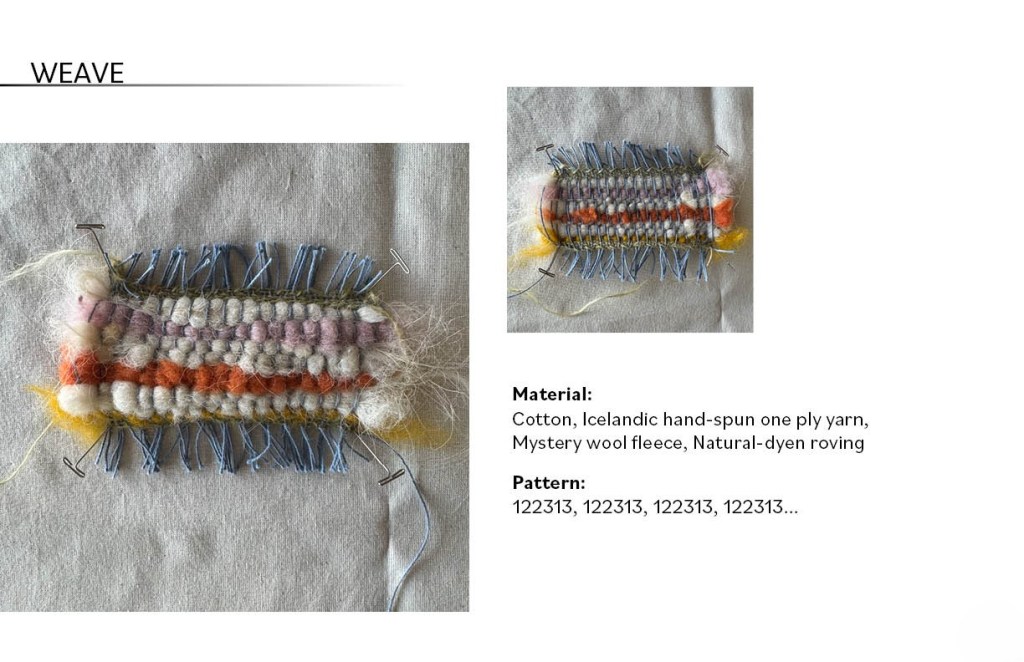

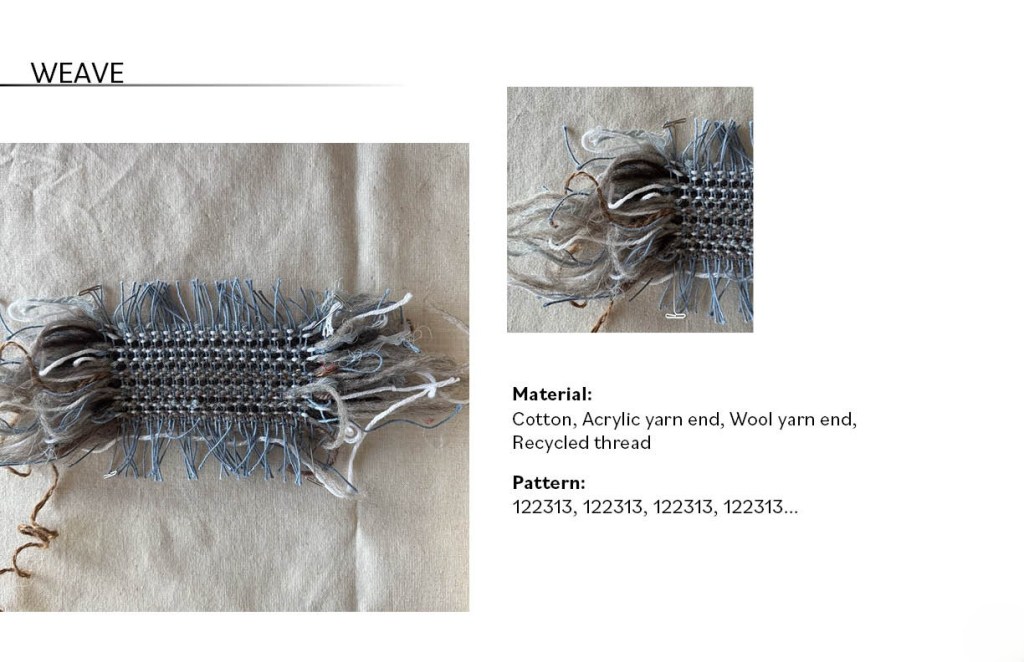

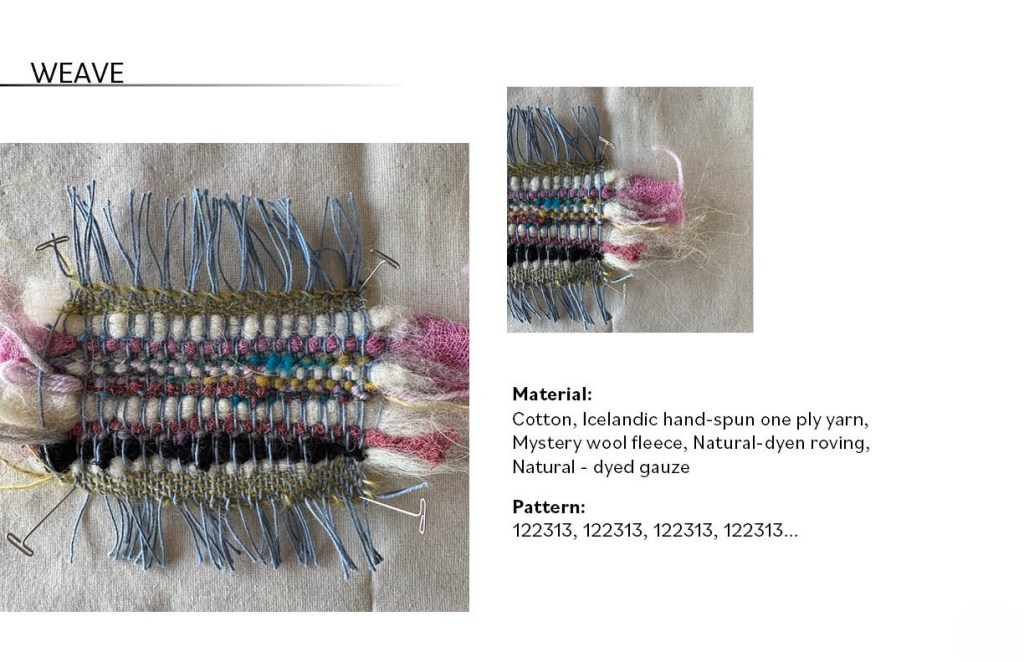

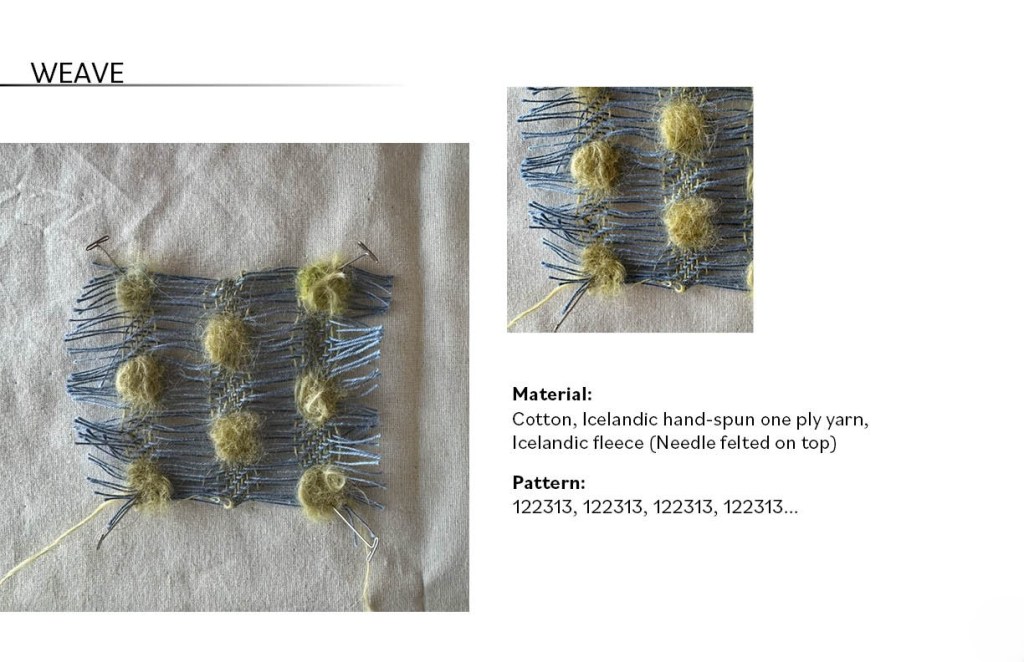

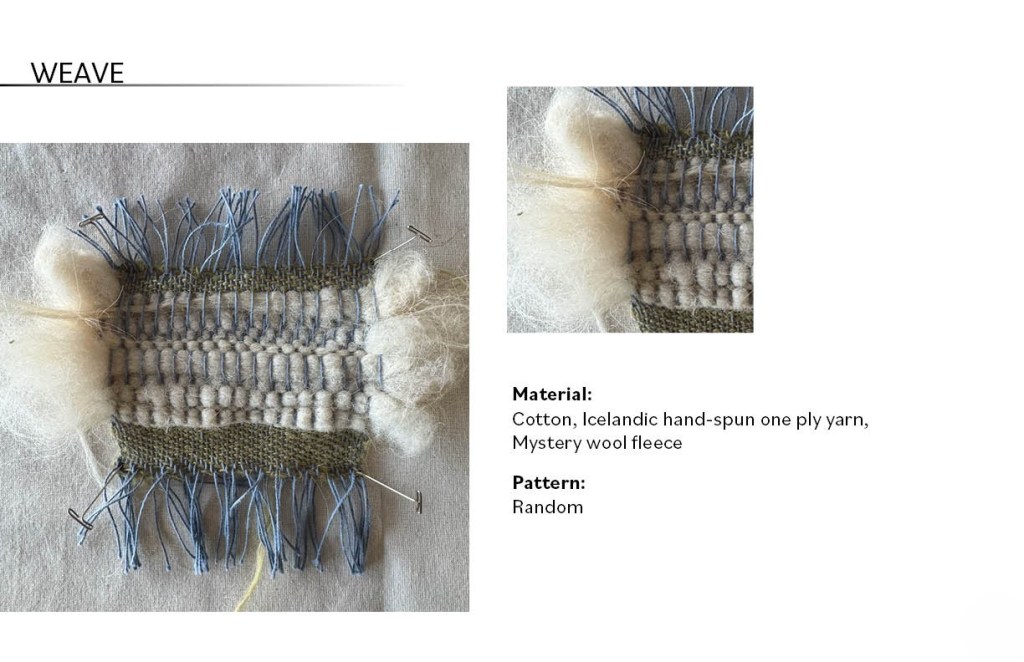

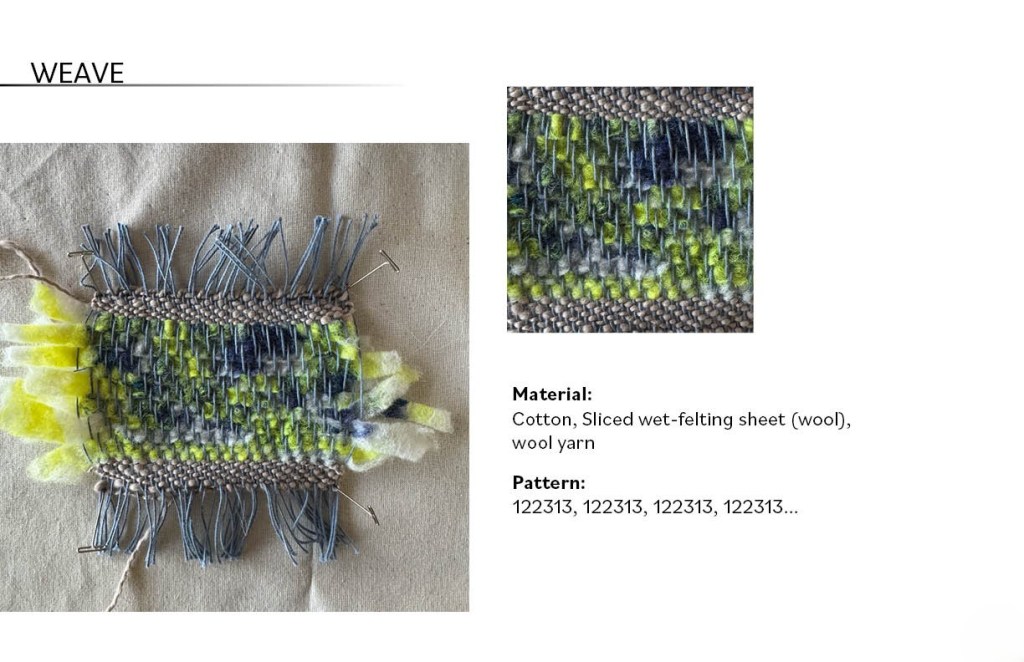

For this project, I divided my material exploration into weaving. This focus enabled me to deepen my understanding of textile processes, from fiber to fabric, and to consider how waste materials—often overlooked in production—can be reintegrated into meaningful and creative practice. My approach was grounded in experimentation, curiosity, and a willingness to embrace the unexpected.

This was my first time working with a four-shaft table loom, and learning how to operate it was an ultimately rewarding experience. I started by watching YouTube tutorials and, unsurprisingly, made some common beginner mistakes. For instance, I didn’t calculate the number of warp threads properly when setting up the loom, which led to a weird warp number. But these initial hiccups helped me understand the logic of the loom, and once I got the hang of it, the samples started to turn out surprisingly well. From there, I kept experimenting—playing with different material combinations—until I reached the maximum warp length.

All of the materials used in my weaving samples were 100% waste. I worked with leftover bits from previous knitting projects and slub from wool carding—the end bits that would usually be discarded. The act of weaving gave these materials a second life.